On ships and in ports around the world, plants, algae and marine animals such as barnacles find homes on whatever surfaces they can reach, a problem that costs the shipping industry billions of dollars each year.

Known as “marine fouling,” these organisms are adapted to living on all manner of surfaces. Marine fouling accumulated on a ship’s hull can increase drag so much that a captain must use up to double the typical amount of fuel to move a ship through the water.

A team of polymer chemists in Florida State University’s Department of Chemistry and Biochemistry is developing a new antifouling coating to keep these sea creatures at bay. The work is funded through a new $510,000 grant from the U.S. Office of Naval Research, or ONR.

“I think marine fouling has been a problem ever since the first person put the first boat in the water,” said Joe Schlenoff, Robert O. Lawton Professor of Chemistry. “We invented this new antifouling coating, and now we have a chance to enhance its effectiveness and to prove it actually works.”

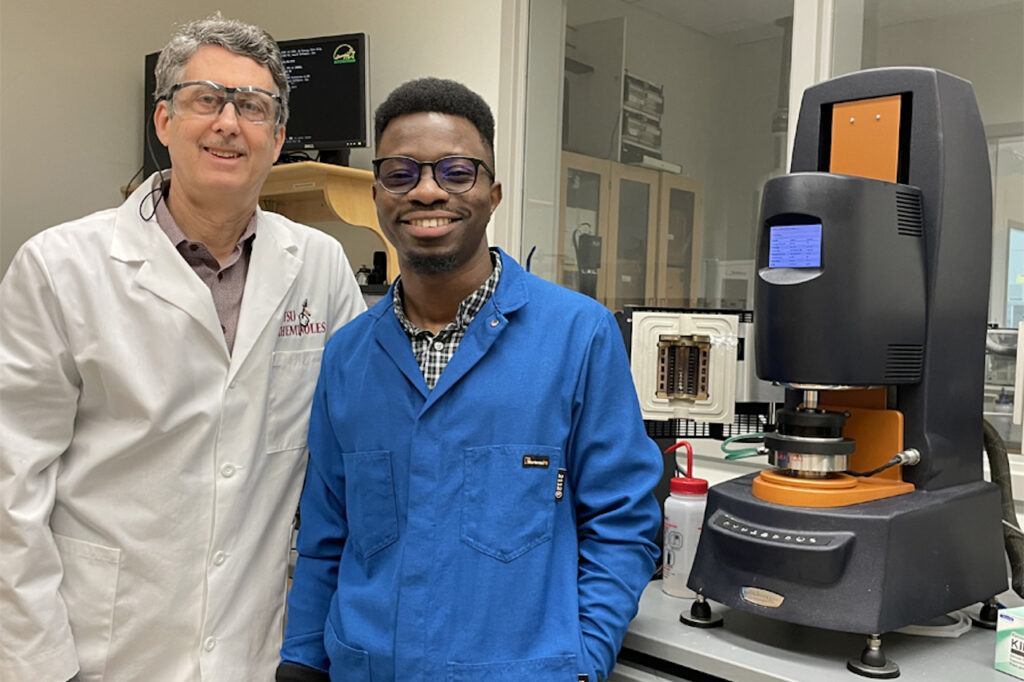

Researchers: From left, Joe Schlenoff, Robert O. Lawton Professor of Chemistry, and graduate student John Akintola. They submitted a patent for an invention they call zwitterglass, a material made from a blend of positively and negatively charged polymers. It can be used as an antifouling coating to protect ships and marine infrastructure from the growth of algae and marine animals such as barnacles. (Courtesy of Joe Schlenoff)

Various antifouling coatings already exist, but many of these release toxic chemicals into water that can harm marine organisms. Schlenoff’s new coating does not contain leachable materials, and it can be sprayed onto a surface using water instead of solvents that contain volatile organic compounds, making it a more environmentally friendly alternative. It is also tougher than the gel-like coatings used in some other antifouling finishes.

The coating uses a substance invented by Schlenoff called “zwitterglass,” a material made from a blend of positively and negatively charged polymers.

Despite a high water content, zwitterglass is glassy and hard, rather than soft and gel-like. That tough material won’t degrade as quickly from the wear and tear of a marine environment, and the high water content makes it more difficult for waterborne animals to latch onto it the way they would take hold of something solid like a rock or piece of metal.

Schlenoff invented this antifouling coating last year. He and graduate student John Akintola recently submitted a patent for the formula with the help of the FSU Office of Commercialization. The Office of Commercialization will assist the inventors throughout the patenting process and work with companies to turn zwitterglass into a commercial product.

This grant will allow Schlenoff’s team to further explore how the coating works against marine organisms and refine its composition. As part of ONR’s efforts to defeat fouling, the group will have access to worldwide facilities that test the efficiencies of various coatings. They will also research the mechanism behind the antifouling behavior.

Schlenoff has spent his entire academic career at FSU studying applications and properties of water-soluble polymers. Funding from federal agencies such as the National Science Foundation and the National Institutes of Health helped build the knowledge that led to the zwitterglass material.

“This is another example where fundamental research over many years translates into effective applications,” he said. “Funding for basic research increased our understanding of how to develop new materials. And now we have a new material that looks very promising, and this is an exciting opportunity to refine it, take our best coating, and then put it through the rigorous testing that the Navy offers.”